HACCP Guidance for Food & Beverage (F&B) Operations

What is HACCP?

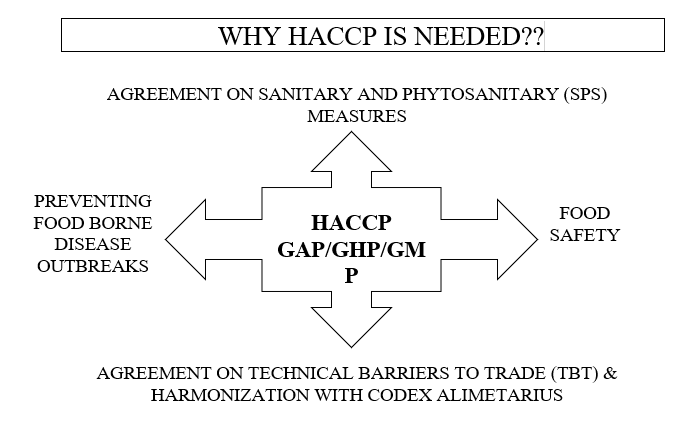

HACCP (Hazard Analysis and Critical Control Points) is a systematic, preventive approach to food safety. It identifies, evaluates, and controls hazards (biological, chemical, and physical) that could compromise food safety in the production, preparation, and service of food.

It is an internationally recognized system and is often a regulatory requirement in many countries for food businesses.

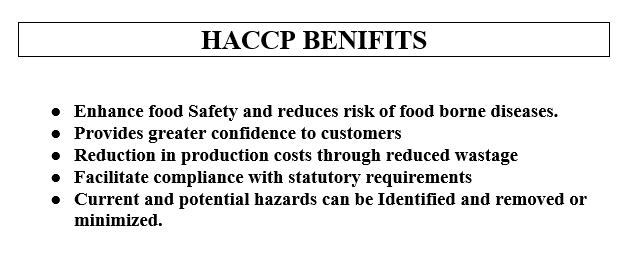

- Prevents foodborne illnesses by controlling potential hazards.

- Ensures compliance with local and international food safety regulations (e.g., FSSAI in India, FDA in the U.S.).

- Builds customer trust and brand reputation.

- Minimizes the risk of costly food recalls or legal issues.

7 Principles of HACCP

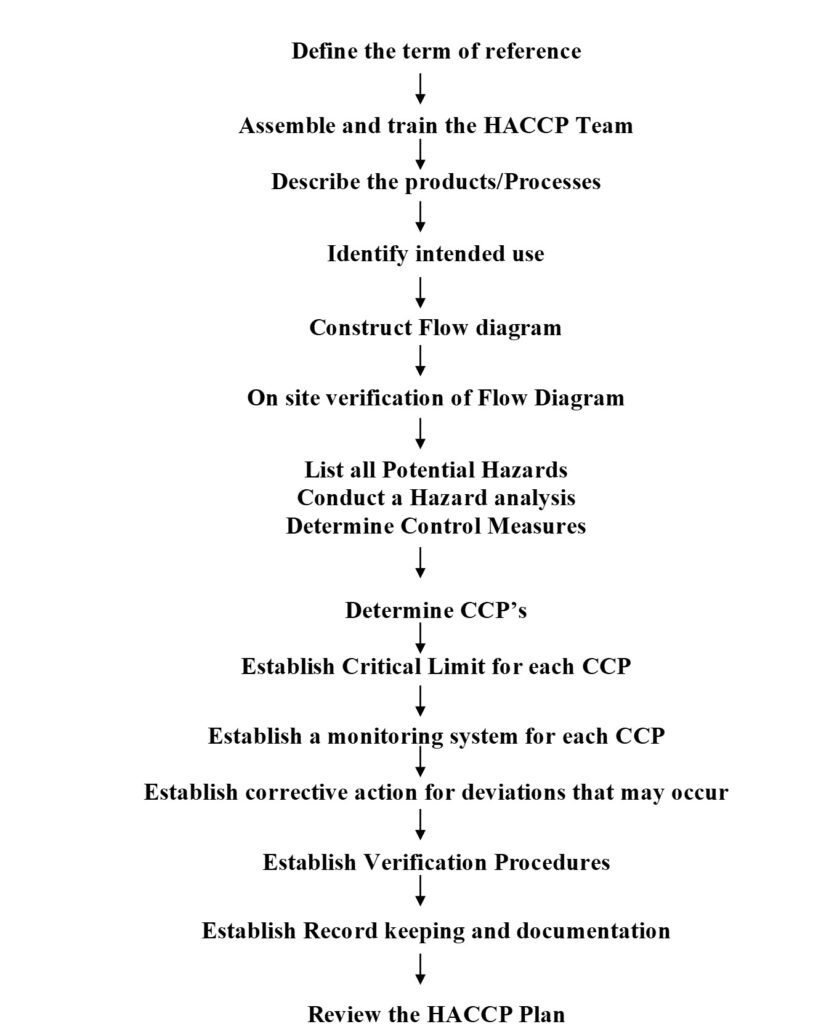

- Conduct a Hazard Analysis

Identify potential hazards (biological, chemical, or physical) in every step of your process—from receiving raw materials to serving food.

- Determine Critical Control Points (CCPs)

Identify key stages where hazards can be prevented, eliminated, or reduced to safe levels (e.g., cooking, chilling, storage).

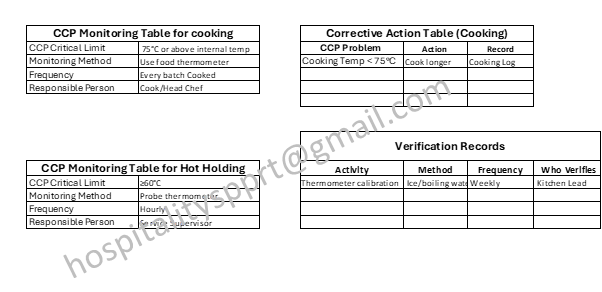

- Establish Critical Limits

Set measurable limits at each CCP (e.g., cook chicken to 75°C or higher to kill bacteria).

- Establish Monitoring Procedures

Define how and when you will monitor each CCP (e.g., using a food thermometer during cooking).

- Establish Corrective Actions

Plan what to do if a CCP is not within its critical limit (e.g., if the fridge is above 5°C, discard perishable items stored in it).

- Establish Verification Procedures

Confirm that the HACCP system is working effectively through audits, reviews, and sample testing.

- Establish Documentation and Record-Keeping

Maintain detailed records of hazard analysis, monitoring results, corrective actions, and audits for traceability and compliance.

- Form a HACCP Team: Include kitchen supervisors, quality control staff, and management.

- Create a Flow Diagram: Map out every step of your food process.

- Customize Your HACCP Plan: Tailor it to your specific menu, equipment, and operation scale.

- Train Staff: Ensure everyone understands hygiene, critical control points, and corrective actions.

- Review Regularly: Update your HACCP plan with any changes in menu, suppliers, or processes.